Predictive Planning and Supply Chain Optimization for Print and Packaging

Plan Ahead: Automate Scheduling and Maximize Efficiency

Introduction

In the world of printing and packaging, the success of a production is not only measured when the machine starts, but is built much earlier: during the planning phase.

It is precisely during pre-production that margins are defined, delays are prevented, and quality and customer satisfaction are determined.

However, when this phase is managed with disconnected tools – like Excel sheets, emails, and scattered documents – risks multiply: errors, rework, time loss, and misunderstandings between departments.

Wsc Printer responds to this challenge with an intelligent and integrated planning system. All departments, from sales to technical, to prepress and the customer, operate on a single digital flow.

The result? More clarity, fewer errors, on-time production starts, and processes that flow smoothly and are traceable.

Real Impact: Numbers That Speak

- ⏳ -60% production start time

Thanks to automation of approval flows and centralization of technical files, Wsc Printer eliminates downtime between order confirmation and job start... - 🔁 -45% rework

Unintentional file duplication, outdated versions or incorrect specification entries are among the main causes of rework... - 💰 +35% cost estimation accuracy

Estimates are often based on historical or hypothetical data, with high margins of error... - 📨 +50% faster customer approval handling

With Wsc Printer's workflow module, the customer receives automatic notifications with documents to approve... - 🔗 100% integration with prepress and production

Every piece of information collected during planning is immediately accessible to prepress and machines... - 📁 A single data source for all job information

Each element of the job is collected in a single digital sheet. No duplication, no out-of-context information...

The Tangible Benefits of Automated Planning

- 🧠 Pre-production automation

Repetitive tasks – like data entry, manual file sending, version control or task notification – absorb time... - 🔄 Structured approval workflows

Approval processes become traceable, intelligent and coordinated... - 🧾 Intelligent file control

Before a file enters production, Wsc Printer analyzes it automatically... - 📊 Predictive material planning

Each planned job is cross-referenced with the warehouse database... - 📌 Custom templates for each type of job

Each type of product can be saved as an operational template... - 🧹 Direct connection with job tickets and scheduling

Everything planned automatically becomes an integral part of the job ticket...

Annual Economic Loss: The Price of Inaction

- 🕒 Hours lost collecting and verifying info

- ❌ Errors in transcribing technical specifications

- 🔄 Graphic rework due to incorrect or outdated files

- 💸 Material waste due to incorrect settings or outdated layouts

- 📥 Delays due to forgotten or partial approvals

- 🤯 Organizational stress due to lack of global vision

- 💸 The real cost of non-automated pre-production

How Wsc Printer Solves Every Resource Planning Problem

The pre-production phase no longer has to be a bottleneck. With Wsc Printer, every step becomes an intelligent, fluid, and interconnected digital process.

From offer creation to file verification, from customer approval to automatic job ticket generation, every activity is:

- ✅ Tracked

- ✅ Synchronized

- ✅ Confirmed in real time

Information no longer gets lost in emails, local folders and Excel files...

- ✅ Fewer errors thanks to automatic checks and structured approvals

- ✅ Less wasted time thanks to automation of repetitive tasks

- ✅ Greater efficiency in managing files, materials, roles and communications

- ✅ Maximum responsiveness to changes, urgencies or last-minute requests

- ✅ Improved collaboration between sales, technical, prepress and customer

- ✅ A continuous and transparent flow, where each phase is under control

💡 Pre-production is no longer a critical point. It becomes your competitive advantage.

Everything You Need to Know About Automated Planning

- How can I structure approval flows automatically?

- With Wsc Printer you can create custom workflows based on job type, with approval steps for customer, graphic and sales departments...

- Can I know right away if a file is suitable for printing?

- Yes. The system automatically checks resolution, format, margins and colors...

- How is versioning of files in progress managed?

- Each revision is saved in an orderly and consultable way...

- Can I check if materials are available before confirming the job?

- Yes. The planning module is connected to the warehouse and signals stock shortages in advance...

- Can the customer be involved in the process?

- Of course. The customer accesses a portal where they can approve, reject or comment on documents...

- Can the system suggest required operations?

- Yes, based on the product type and set parameters, Wsc Printer automatically proposes the expected process sequence.

- How are activities assigned to the technical team?

- Each task is automatically assigned to a role or operator according to defined rules...

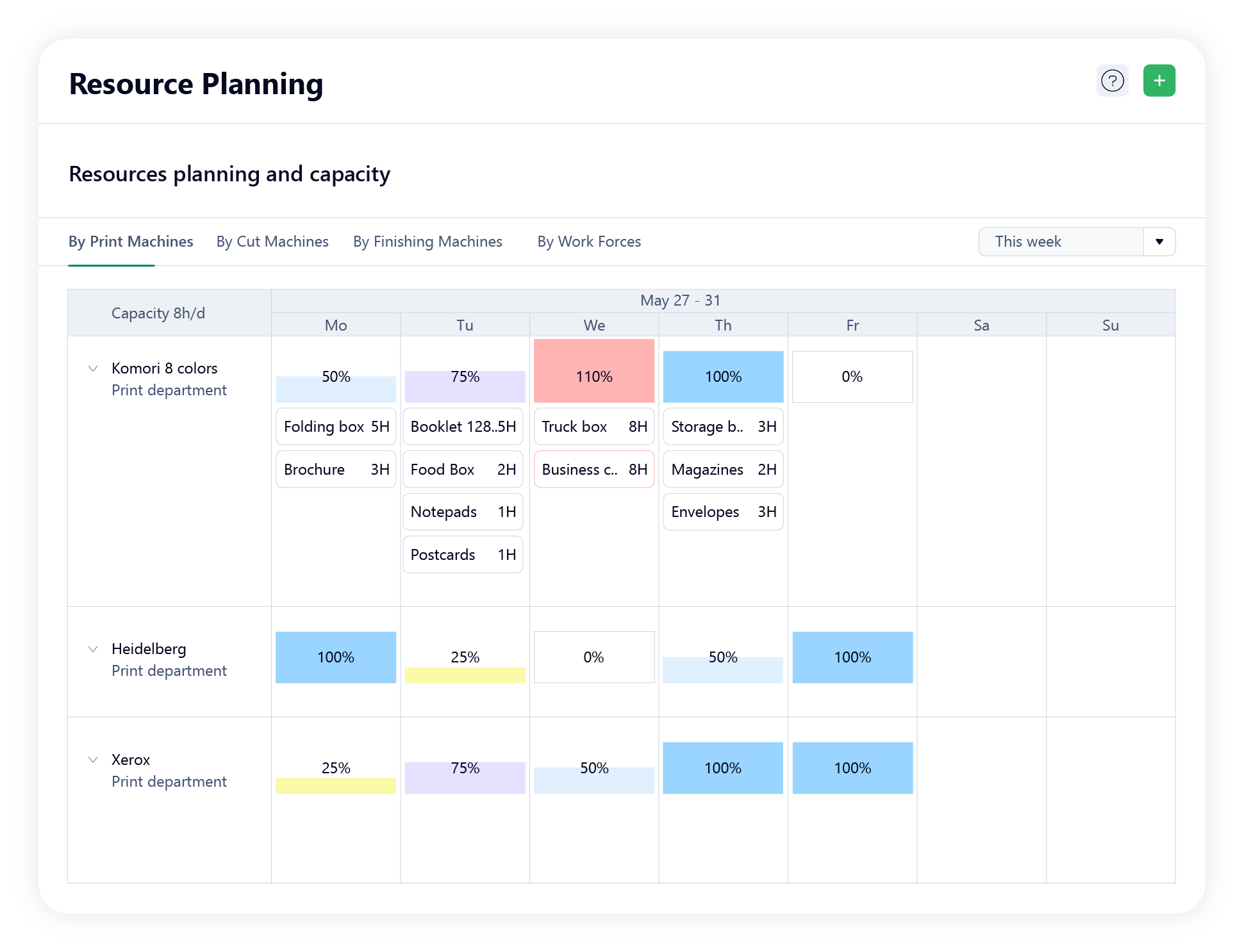

- Can I have a global view of all planned activities?

- Yes, through dashboards and calendar views you can filter by department, customer, job and progress status...

- Can the system also plan recurring jobs?

- Of course. You can create planning templates for recurring jobs...

- Can I analyze variances between estimate and actuals?

- Yes. Wsc Printer tracks times, materials and changes, allowing comparison between estimates and actuals...

Conclusion

Digitizing pre-production is no longer just an option, but a strategic necessity for printing and packaging companies that want to stay competitive. Through process automation, information centralization and structured interdepartmental collaboration, Wsc Printer turns every phase of planning into a concrete operational advantage.

Reducing errors, speeding up timelines, improving quality and ensuring real-time global visibility: these are the pillars for building a modern and efficient production system. With Wsc Printer, pre-production is no longer a bottleneck but becomes the engine of operational excellence.

Choosing automated planning means investing in control, transparency and growth. The future of printing starts with intelligent pre-production.

Get weekly updates

in your inbox!